Aluminum Busbars | Durable & Efficient Electrical Conductors

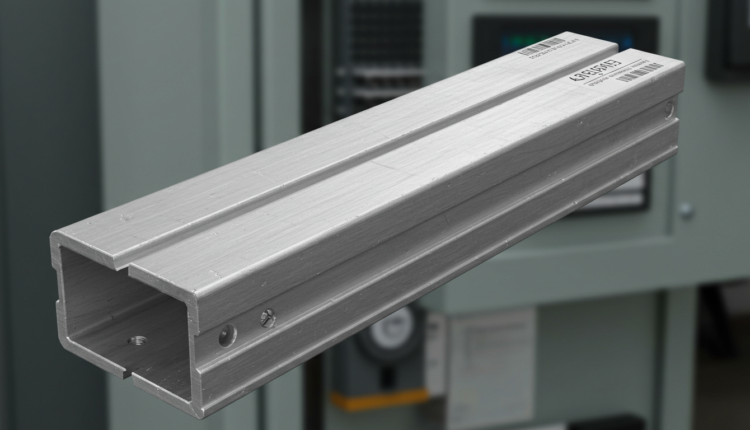

Aluminum busbars serve as essential components in electrical systems, facilitating efficient electrical conduction in various applications. These bus bars are critical for distributing electrical power, crafted from aluminum alloys that enhance conductivity while maintaining a lightweight profile. The choice of aluminum as the primary material allows for significant weight reductions compared to traditional alternatives, making these solutions ideal for both industrial and commercial electrical installations. Understanding the role and function of electrical busbars is vital for optimizing performance in any setup. By utilizing aluminum conductors, these systems achieve remarkable efficiency, effectively addressing the needs of modern electrical infrastructure.

Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions | Defining Electrical Busbars

Electrical busbars serve as crucial electrical conductors within various systems, facilitating the distribution of power across different components. Aluminum busbars are a prominent choice due to their impressive electrical conductivity, lightweight nature, and resistance to corrosion, primarily through the formation of aluminum oxide. These busbars often come in configurations using materials like copper-clad aluminum, combining the benefits of both metals to optimize performance and minimize costs.

The design of aluminum busbars typically incorporates aluminum alloys and extruded aluminum for strength and conductivity. This versatility makes them suitable for a range of applications, including electric vehicle charging stations, where efficient power transfer is essential. The capability of these busbars to handle substantial electrical loads while remaining lightweight enhances their appeal in modern electrical infrastructure. Aluminum busbars: high-conductivity & lightweight electrical solutions are thus an integral part of efficient energy systems.

Key Features of Aluminum Busbars

Aluminum busbars are recognized for their high conductivity, making them essential components in modern electrical engineering. These conductors efficiently transport electrical energy across various electrical systems, significantly outperforming traditional copper wires in many applications. The use of 6061 aluminum in busbar construction ensures durability while maintaining a lightweight profile. This is particularly beneficial in scenarios such as installing busbars in electric vehicles, where weight reduction is critical.

Another key feature of aluminum busbars is their versatility in design and materials. Options such as cast aluminum and stainless steel offer flexibility for different electrical installations. These features play a crucial role in optimizing electrical wiring, ensuring reliable performance in various industrial and commercial environments. As part of Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions, these attributes enhance the overall efficiency and efficacy of electrical systems.

Advantages of Aluminum Busbars

Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions offer significant advantages in modern electrical systems due to their exceptional high-conductivity properties combined with a lightweight nature. This makes them ideal for various applications, including battery systems in new energy vehicles where minimizing weight is crucial. As a base metal, aluminum is often favored over steel and copper, presenting a cost-effective alternative while maintaining the required performance levels for electrical connectors and wiring. Their efficient design allows for reduced cross-sectional areas, which translates to space-saving features in compact electrical systems. The use of aluminum powder in manufacturing enhances conductivity, ensuring these busbars effectively transmit electricity while minimizing losses, making them a preferred choice for cables and other integral components of power distribution.

High-Conductivity Properties

Aluminum busbars: high-conductivity & lightweight electrical solutions excel in conducting electrical current due to their efficient conduction properties. They are designed to facilitate seamless electrical connections while minimizing energy loss. Compared to traditional copper conductors, conductive aluminum busbars offer an attractive alternative for various applications. The use of electrical-grade aluminum in their construction ensures that they can handle substantial loads without compromising performance, making them a reliable choice in electrical systems.

The lightweight characteristics of these busbars further enhance their appeal. Their reduced mass allows for easier handling and installation, which can lead to lower labor costs in projects. Despite being lighter than copper busbars, conductive aluminum busbars can efficiently transport electricity, proving that lightweight busbar-solutions aluminum do not sacrifice conductivity. This balance of high conductivity and lightweight design positions aluminum busbars as an ideal solution for modern electrical engineering challenges.

Lightweight Characteristics

Lightweight characteristics play a crucial role in the effectiveness of aluminum busbars. Utilizing high-grade aluminum busbars allows for significant reductions in weight compared to traditional copper alternatives. This lightweight feature enhances the efficiency of aluminum busbar systems, making them easier to handle and install. The use of high-quality aluminum busbars can lead to streamlined designs that occupy less space while still providing high conductivity. Different aluminum busbars can be customized to meet specific requirements, allowing for versatility in various applications.

The aluminum grade busbars often demonstrate exceptional strength-to-weight ratios, offering robust solutions without the bulk. Aluminum bus solutions are ideal for industries that prioritize performance and efficiency, reducing the structural load on frameworks. Aluminum busbar designs vary widely, catering to diverse environments and electrical needs. Depending on the application, aluminum bus bars can be tailored to optimize their lightweight properties, ensuring a perfect balance of durability and functionality.

Types of Aluminum Busbars

Aluminum busbars are a key component in the realm of electrical distribution, known for their high-conductivity and lightweight characteristics. These electrical busbar products come in various options tailored for specific applications, ensuring optimal performance. Selecting the right aluminum busbar involves considering aluminum busbar specifications which outline the necessary dimensions and capacities. High-quality aluminum bus bars are often crafted from top-grade aluminum alloys, designed to meet diverse needs within electrical systems. Different aluminum busbar grades are available, providing flexibility in choosing the appropriate aluminum bus components for both industrial and commercial settings. With a wide array of aluminum busbar options, engineers can identify the most effective solution for their electrical requirements.

Conductive Aluminum Busbars

Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions excel in numerous applications due to their efficient conductivity and reduced weight. Custom aluminum busbar designs allow for unique configurations that enhance electrical performance while minimizing space. For specific uses like battery busbars, manufacturers often utilize custom-shaped aluminum busbars to ensure optimal fit and function. The option for copper-clad aluminum busbars provides a balanced alternative, combining the benefits of both materials in one solution.

Copper busbars continue to dominate in many sectors, but the innovative features of aluminum busbars are making them competitive. Comprehensive conductive aluminum options present effective solutions for various power distribution needs. Threaded aluminum bus configurations facilitate easy installation and adaption across different applications. As industries strive for efficient and lightweight electrical solutions, copper busbar manufacturing may see a shift towards incorporating more aluminum bus bars into their product lines.

Comparison with Conductive Copper Busbars

Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions offer several advantages over traditional conductive copper busbars. For instance, tin-plated aluminum bus bars can significantly reduce the risk of corrosion compared to their uncoated counterparts. Busbar manufacturing processes often favor aluminum due to its lightweight characteristics, which allow for easier handling and installation in various busbar applications. These benefits can lead to cost savings in both material and labor while maintaining high-performance standards.

Conductive copper busbars, such as nickel-plated copper busbars or chalco copper busbars, are known for their superior conductivity. However, the weight and cost of copper can be drawbacks for some projects. On the other hand, electrical-grade aluminum provides a balance of conductivity and reduced weight, making it a viable option for many electrical specifications. Busbar products like tinned aluminum bus or tin-coated aluminum bus are designed to enhance performance while ensuring durability in diverse environments, allowing engineers to choose the best material for their specific requirements.

Applications of Aluminum Busbars

Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions serve a variety of applications across different sectors, effectively meeting electrical-grade aluminum standards. These high-quality aluminum solutions are ideal for industrial settings, providing efficient power distribution through conductive designs. The use of tin-plated aluminum bus enhances corrosion resistance, making them suitable for demanding environments. Hard aluminum bars and laminated busbars offer excellent conductivity, positioning aluminum busbars as viable copper bus alternatives. Their lightweight characteristics facilitate easier handling and installation, while ensuring reliability in commercial electrical solutions. The versatility in sizes and configurations of these aluminum bars allows for tailored solutions to meet specific project requirements.

Industrial Uses

Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions play a crucial role in various industrial settings. Companies often utilize aluminum conductors due to their lightweight characteristics, providing easier installation and reduced structural support requirements. Pre-assembled busbars streamline the setup process in factories, while laminated busbars consist of multiple layers that enhance conductivity and thermal management. In high-demand environments, large busbars are essential for efficient energy distribution, ensuring seamless operations across machinery and systems.

Industrial applications frequently rely on the superior properties of aluminum in busbar design. Aluminum offers remarkable conductivity, making it an ideal choice for high-quality bus bars that require optimal performance. Single-layer busbars are commonly used for straightforward applications, while more complex systems may deploy compact bus bars or tin-coated copper bus configurations. Ultimately, aluminum bars deliver efficient solutions in demanding environments where reliability and performance are paramount, establishing aluminum as an excellent conductor of heat and electricity.

Commercial Electrical Solutions

Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions serve as key components in commercial electrical installations, ensuring efficient power distribution. These aluminum components provide a reliable alternative to traditional copper bus systems. Their lightweight nature simplifies the handling of aluminum bars outdoors, while the aluminum core minimizes the risk of corrosion. Many commercial applications benefit from using predrilled/tapped copper busbars alongside their own busbars, allowing for versatile configurations that optimize space and functionality.

The use of tinned busbars enhances conductivity and protects the bus bar surface from environmental factors. In commercial settings, aluminum positions allow for sustainable and cost-effective energy solutions. With a variety of aluminum products available, optimizing the design and installation of bus bars becomes achievable. A well-planned layout that considers sizing and capacity will ensure the longevity and effectiveness of the electrical system, making aluminum busbars an ideal choice for modern commercial electrical solutions.

Design Considerations for Aluminum Busbars

Designing effective aluminum busbars requires careful consideration of various factors to ensure optimal performance and reliability. This involves selecting the right busbar sizes and choosing aluminum fasteners and mounts that provide durability and stability. The use of clean aluminum contributes to the conductivity of these busbars, making them superior bus bars in many applications. Potential equalization busbars are essential for managing varied electrical loads, while laminated busbarsquick enhance flexibility and space savings. Integration with aluminum rails can further streamline design, making the installation process efficient. Emphasizing these elements is vital in achieving the benefits of Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions.

Sizing and Capacity of Aluminum Busbars

Understanding the sizing and capacity of aluminum busbars is vital for their effective application in electrical systems. Flat bus bars are often preferred for their ability to optimize space and enhance connectivity. Selecting the appropriate grade aluminum, particularly specific aluminum alloys, can significantly impact performance and longevity. Using bus technology that incorporates various aluminum bar options ensures optimal conductivity. Bus connectors designed for aluminum can accommodate flat and round angle designs, providing flexibility in installation.

Capacity calculations are crucial to ensure the busbars can handle the electrical load without overheating. Bus boards equipped with bus bar holes facilitate proper mounting and airflow. Recognizing that aluminum corrodes over time emphasizes the importance of protective coatings or treatments. Properly sizing aluminum busbars involves considering both the current capacity and the thermal management strategies needed to maintain efficiency. Effective design ensures that Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions meet the demands of their intended applications.

Thermal Management Strategies

Effective thermal management is crucial for the performance and longevity of Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions. Utilizing closed aluminum oxide coatings can enhance the thermal properties of the busbars while improving insulation. Different size aluminum bus bars require tailored thermal strategies to manage heat dissipation effectively, ensuring that the temperature remains within operational limits. By choosing top-grade aluminum alloys and carefully designing aluminum profiles, manufacturers can create bus systems that minimize thermal stress and enhance overall performance.

Optimal thermal management strategies include the implementation of thermal conductive materials and efficient bus bar distribution methods. Various bus bar arrangements, such as those provided by phoenix busbars, can significantly affect heat flow within electrical systems. Proper sizing and spacing of busbars help to prevent hotspots, while maintaining the functionality of the overall electrical infrastructure. For best results, engineers should consider the characteristics of the chosen aluminum grade in relation to the thermal demands of the application.

Installation Practices for Aluminum Busbars

Effective installation practices are crucial for optimizing the performance of Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions. A detailed bus bar plan must be developed, ensuring the bus bar width corresponds to the required current-carrying capacity. Selecting the exact aluminum grade enhances durability and efficiency, while deciding whether to use wider or thinner bus bars can impact both weight and performance. Incorporating aluminum threads and considering the use of tin-coated aluminum bars can further improve connectivity and reduce corrosion. Ensuring there is enough aluminum for the intended application requires careful measurement and selection of each aluminum piece to guarantee reliable electrical solutions. In some configurations, bus bars such as the rex coil can be employed to manage electrical flow effectively, underscoring the importance of precision during installation.

Required Tools and Safety Precautions

A well-prepared toolkit is essential for the successful installation of Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions. Necessary tools include wire cutters, crimping tools, and torque wrenches to ensure secure connections of tinned aluminum bars to various electrical equipment. Using the right aluminum grade is crucial for achieving optimal performance in electrical applications. Custom aluminum components should be measured against the appropriate busbar size reference, allowing for effective integration into existing systems.

Safety precautions must not be overlooked during the installation process of aluminum busbars. Always wear appropriate personal protective equipment (PPE) such as gloves and safety glasses to protect against sharp edges and potential electrical hazards. Proper handling techniques for raw aluminum and conductive metal layers are vital to prevent accidents. Engaging with knowledgeable aluminum people can enhance understanding of best practices and guide installers in optimizing their bus bar solution.rex for maximum high conductivity and efficiency.

Best Practices for Installation

Proper installation of aluminum busbars hinges on meticulous attention to detail, particularly regarding the selection of a detailed aluminum alloy. Each bus bar entry should comply with electrical specifications to ensure optimal performance in various electrical applications. It is crucial to consider the unique requirements of current conductors and the specific needs of your electrical infrastructure. Utilizing aluminum forms that offer the ideal balance of strength and conductivity can enhance efficiency for high-power applications, reinforcing the reliability of the entire system.

Safety should always be prioritized during installation. Employ tools specifically designed for handling aluminum busbars, as this promotes accuracy and minimizes the risk of damage. Investigating the unique requirements of clean energy applications can further aid in meeting the demanding challenges of modern electrical infrastructures. Chalco aluminum, recognized for its superior properties, serves as a prime choice in such contexts, ensuring that Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions are installed effectively and safely.

Conclusion

Aluminum busbars stand out as high-conductivity and lightweight electrical solutions, making them essential for various electrical applications. These busbars provide an efficient means of conducting electricity, showcasing the advantages of aluminum over traditional materials. While aluminum lies at the core, the combination of zinc/aluminum can enhance properties, further improving performance. The discussion around Aluminum Busbars: High-Conductivity & Lightweight Electrical Solutions highlights not only the benefits but also the versatility and efficiency these components bring to both industrial and commercial sectors. Understanding these key aspects is crucial for anyone involved in electrical design and installation.

FAQS

What advantages do aluminum bus bars offer for electrical infrastructure compared to copper bus bar options?

Aluminum bus bars, known for their high conductivity and lightweight properties, are often preferred over copper bus bar options due to their excellent performance as electricity conductors. Pure aluminum used in aluminum bus bars is not only cost-effective but also provides significant capacity for lightweight electrical solutions. Additionally, various aluminum busbar designs, crafted from top-grade aluminum alloys, contribute to efficient electrical infrastructure needs, making aluminum an excellent conductor of heat and electricity.

How do the capacity aluminum busbars perform compared to traditional copper bus bar options in electrical applications?

Capacity aluminum busbars are highly efficient for electrical applications due to aluminum being an excellent conductor of heat and electricity. These aluminum conductors are crafted from top-grade aluminum alloys, ensuring they meet the demands of various electrical systems. In comparison to copper bus bars, aluminum busbars present a lighter solution, which is beneficial for reducing overall weight in installations. Additionally, copper-clad aluminum busbars combine the advantageous features of both metals, offering a cost-effective and lightweight choice while still maintaining an efficient capacity for current transmission. Whether opting for uncoated aluminum bus or advanced electrical-grade aluminum busbars, users can find an aluminum variety that suits their specific electrical requirements.

What specifications should I consider when selecting an aluminium busbar for my electrical system?

When selecting an aluminium busbar for your electrical system, it is important to consider specifications such as the type of aluminium conductor, the thickness of the aluminium busbar, and whether you need copper clad aluminum options. Additionally, ensure that the aluminium busbars are crafted from top-grade aluminum alloys for optimal performance. You may also want to look into the dimensions, such as wider/thinner bus bar options, as well as the busbar mounts and round angle aluminum configurations. This way, you can ensure that your conductive bus meets the requirements for efficiency and safety in your application. For a quick quote on aluminium busbars that suit your needs, it’s advisable to refer to trusted suppliers who offer specialized options.

How are aluminum busbars constructed to optimize electrical conductivity and what materials are used in their production?

Aluminum busbars are crafted from top-grade aluminum alloys, ensuring that they provide excellent performance in electrical applications. Given that aluminum is an excellent conductor of heat and electricity, these busbars offer significant advantages over copper busbar options. Depending on the specifications, aluminum busbars can be designed for various bus bar entries, enhancing their compatibility with different electrical systems. For a quick quote on aluminum busbars, it’s important to consider the specific requirements, including copper-clad aluminum busbars when applicable.

How do the properties of electrical grade aluminum in aluminum busbars compare with conductive metals such as copper-clad aluminum busbars in high-performance applications?

Electrical grade aluminum is an excellent conductor of heat and electricity, which makes aluminum busbars a viable alternative to traditional conductive metals like copper-clad aluminum busbars. Aluminum busbars offer advantages in terms of weight and cost efficiency while maintaining high conductivity. For those seeking quick quotes on aluminum busbars or specific aluminum profiles, it is essential to consider the busbar end application and performance requirements in your electrical system or setup.

How do performance and pricing of aluminum busbars compare with copper-clad aluminum busbars in various applications?

When selecting an aluminum busbar depending on performance and price, it’s important to note that aluminum is an excellent conductor of heat and electricity, making it a viable option compared to copper-clad aluminum busbars. Many businesses seek quick quotes for aluminum busbars, especially when they consider an aluminum profile that fits their application needs. Numerous busbars offers provide competitive pricing, emphasizing the quick turnaround and availability, which allows for tailored solutions in projects such as those using bus bars like the Rex Coil in various electrical setups.

What are the benefits of using aluminum busbars in electrical systems and how do they compare to copper-clad aluminum busbars?

Aluminum busbars are an excellent choice for electrical systems because aluminum is an excellent conductor of heat and electricity, making them efficient for various applications. When compared to copper-clad aluminum busbars, aluminum busbars often provide quicker installation and more cost-effective solutions. Additionally, for a quick quote on bus bars, manufacturers can provide an aluminium profile tailored to your specific needs, showcasing their versatility in different projects, such as those involving busbars from Rex Coil.

How can I obtain a quick quote for aluminum busbars and what role do copper-clad aluminum busbars play in high-performance applications?

To obtain a quick quote for aluminum busbars, you can contact suppliers who specialize in these products. It’s essential to note that while aluminum is an excellent conductor of heat and electricity, copper-clad aluminum busbars are often used in applications where additional conductivity is required. These busbars provide a cost-effective solution by combining the lightweight advantages of aluminum with the superior conductivity of copper, making them suitable for various electrical applications.

How can I obtain a quick quote for aluminum busbars, and what role do copper-clad aluminum busbars play in high-performance applications?

To obtain a quick quote for aluminum busbars, you can contact suppliers directly through their websites or via request forms, which typically offer a prompt response. In high-performance applications, copper-clad aluminum busbars are often utilized for their efficiency, as aluminum is an excellent conductor of heat and electricity while providing a more cost-effective solution compared to pure copper.

How can I quickly compare aluminum busbars and copper-clad aluminum busbars for my electrical projects?

To efficiently compare aluminum busbars and copper-clad aluminum busbars, you can obtain a quick quote from suppliers who specialize in these products. It’s important to note that aluminum is an excellent conductor of heat and electricity, which makes aluminum busbars a solid option for many electrical applications. When considering various options, remember to evaluate performance against your project’s specific requirements and always ask for a quick quote to make informed decisions regarding bus bars.

Comments are closed.