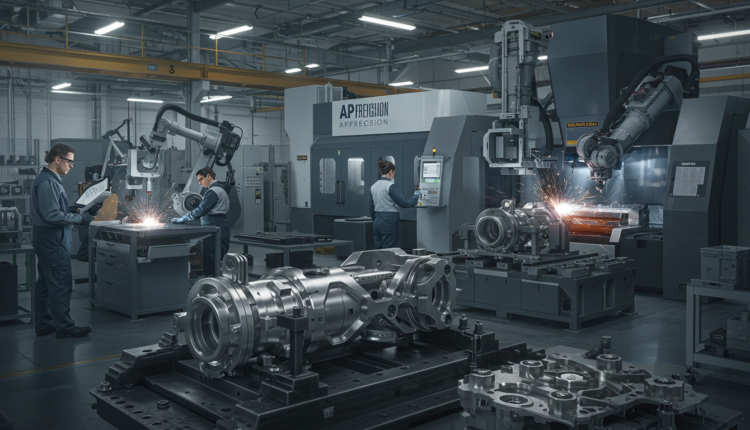

AP Precision: Leading the Way in Advanced Metal Fabrication has established itself as a benchmark in the field of metal working and fabrication. The company specializes in various metal fabrications, utilizing cutting-edge techniques to ensure accuracy and precision in every fabrication process. With a focus on metal forming and the use of high-quality metal alloys, AP Precision addresses the needs of diverse industries that require reliable and innovative metal solutions. By prioritizing advanced technologies and skilled craftsmanship, AP Precision is well-equipped to meet the challenges of the ever-evolving metal industries. Their commitment to excellence in metal fabrication sets them apart as a leader in this competitive market.

- Advanced technologies utilized for increased efficiency and precision

- Skilled workforce dedicated to high-quality craftsmanship

- Comprehensive services including cutting, welding, and assembly

- Focus on meeting specific client needs across various industries

- Commitment to continuous improvement and innovation

- Strong emphasis on quality control and safety measures

- Partnerships with leading suppliers to ensure top-tier materials

AP Precision: Leading the Way in Advanced Metal Fabrication | History and Evolution of AP Precision

AP Precision: Leading the Way in Advanced Metal Fabrication has grown significantly since its founding, evolving from traditional welding methods to incorporating cutting-edge technology. The integration of CNC machining and various welding techniques, including arc welding and laser welding, has allowed the company to work with a wide range of metals such as stainless steel and copper. This transformation has cemented its reputation as a leader in manufacturing, emphasizing accuracy and precision in all fabrication processes.

Over the years, AP Precision: Leading the Way in Advanced Metal Fabrication has embraced advancements in machinery and technology, enhancing its capabilities in sheet metal fabrication and machining. The commitment to innovation has not only improved the quality of products but also increased efficiency in production. This dedication to excellence positions AP Precision as a key player in the metal fabrication industry, continuously pushing the boundaries of what is possible in manufacturing.

Core Values and Mission

At AP Precision: Leading the Way in Advanced Metal Fabrication, a strong commitment to innovation and quality drives the core values of the organization. The company embraces advanced technologies, such as laser technology and additive manufacturing, to enhance its capabilities in fabricating materials like steel and aluminum. By utilizing various alloys and state-of-the-art material handling equipment, AP Precision ensures precision in every project it undertakes. Upholding high standards, the firm also invests in welder certification to maintain a skilled workforce capable of meeting the demands of diverse sectors, including the electronics industry.

Customer satisfaction stands at the forefront of AP Precision’s mission. The organization prioritizes delivering exceptional products that meet unique specifications, reinforcing its position as a leading manufacturer in the field. Continuous improvement and adaptation to emerging technologies ensure AP Precision remains competitive. This dedication to excellence, coupled with a focus on sustainability, underlines the company’s commitment to responsible manufacturing practices that benefit both clients and the environment. AP Precision: Leading the Way in Advanced Metal Fabrication is more than a tagline; it encapsulates the ethos that guides every aspect of the business.

Understanding Metal Fabrication

Metal fabrication encompasses a range of processes crucial for transforming raw materials into finished products. At AP Precision: Leading the Way in Advanced Metal Fabrication, various techniques such as drilling, grinding, and laser-cutting play an essential role in creating components for industries like electronics and machinery. Factories equipped with cutting-edge technology facilitate the design and engineering of intricate electronic devices, ensuring high standards such as AS9100 are met. The incorporation of laser etching allows for precise detailing and customization in fabrication projects, further highlighting the significance of advanced methodologies in meeting modern manufacturing demands. AP Precision: Leading the Way in Advanced Metal Fabrication exemplifies this commitment to quality and innovation.

What is Metal Fabrication?

Metal fabrication represents a series of processes essential to the creation of various metal products and structures. This industry encompasses techniques such as laser cutting, welding, and machining, which are crucial for manufacturers looking to craft components with exact specifications. AP Precision: Leading the Way in Advanced Metal Fabrication takes pride in employing state-of-the-art technology and precision fabrication techniques to deliver high-quality results. The significance of precision metal fabrication cannot be overstated, as it ensures durability and functionality in a wide range of applications.

Precision metal fabrication is vital across numerous industries, including aerospace, automotive, and construction. The ability to utilize advanced metal fabrication techniques allows manufacturers to achieve intricate designs and optimize the strength-to-weight ratio of products. Companies like AP Precision: Leading the Way in Advanced Metal Fabrication focus on leveraging precise fabrication techniques to meet the diverse needs of precision metal industries. By emphasizing quality and innovation, these manufacturers enhance the overall value of their offerings, ensuring they remain competitive in an ever-evolving market.

Importance of Metal Fabrication in Various Industries

The metal fabrication industry plays a crucial role in numerous sectors such as aerospace, automotive, and construction. Companies rely on precise fabrication to meet their specific metal fabrication needs. AP Precision: Leading the Way in Advanced Metal Fabrication exemplifies commitment to producing accurate metal components. By utilizing high-precision equipment and advanced fabrication machinery, AP Precision ensures that each metal fabrication project meets the stringent requirements demanded by various industries.

Various fabrication techniques are employed to create advanced metal components that enhance product performance and safety. Precision sheet metal is a key aspect of this process, as it enables the crafting of intricate designs that require a high level of accuracy. Metal fabrication companies like AP Precision: Leading the Way in Advanced Metal Fabrication continuously innovate their methods to streamline the metal fabrication process. This dedication to quality results in deliverables that not only fulfill immediate design criteria but also contribute to the long-term reliability of the products produced.

The Role of Precision in Metal Fabrication

Precision plays a crucial role in the fabrication industry, particularly in meeting the diverse fabrication requirements across various sectors. AP Precision: Leading the Way in Advanced Metal Fabrication exemplifies the importance of high precision in producing high-quality metal components. Techniques that focus on detailed metal components ensure that the metal material is shaped and assembled with utmost accuracy, resulting in high-precision parts that enhance overall product reliability. With a commitment to excellence, AP Precision continuously innovates to provide top-notch fabrication services that meet the rigorous standards of their clients, solidifying their reputation in the competitive landscape of metal fabrication.

Defining Metal Fabrication Precision

Precision in metal fabrication entails the meticulous process of shaping, cutting, and assembling metal materials into reliable metal products. AP Precision: Leading the Way in Advanced Metal Fabrication employs advanced technology and metal machinery to ensure the production of crucial metal components. Through successful precision sheet metal solutions, the company meets stringent industrial manufacturing requirements. By focusing on detail and accuracy, AP Precision guarantees that every metal part meets or exceeds specifications, ultimately enhancing the overall quality of the final product.

Achieving precision in metal fabrication relies on the integration of advanced techniques and a deep understanding of metal cutting processes. Cost fabrication is optimized through effective use of resources and adherence to best practices in metalworking. AP Precision: Leading the Way in Advanced Metal Fabrication showcases how these methods not only improve efficiency but also contribute to the sustainability of projects. Through commitment to excellence, the company consistently delivers high-quality metal solutions tailored to customer needs.

Benefits of Precision Fabrication Techniques

Precision fabrication techniques provide significant advantages that enhance the efficiency and quality of industrial manufacturing. AP Precision: Leading the Way in Advanced Metal Fabrication employs skilled metal fabricators who utilize advanced machinery to ensure high accuracy in every project. Specific precision sheet fabrication methods allow for precise material preparation, enabling the effective use of welding materials and the precise cutting of used metals. This approach not only addresses complex manufacturing questions but also ensures that the final products meet stringent quality standards.

The lean fabrication approach adopted by AP Precision minimizes waste and reduces production costs while maintaining superior outcomes. By focusing on precision, the company can deliver tailored fabrication services that cater to the unique needs of clients. This results in innovative solutions that not only optimize resource use but also enhance the overall performance of fabricated components. As a result, businesses in various sectors benefit from the enhanced reliability and longevity of their products, solidifying AP Precision’s role as a leader in the field.

| Benefit | Description | Impact on Industry |

|---|---|---|

| High Accuracy | Ensures precise measurements and cuts in metal components. | Enhances product quality and consistency, reducing rework costs. |

| Minimized Waste | Reduces excess material usage through optimized processes. | Lowers production costs and environmental impact. |

| Customized Solutions | Tailors fabrication services to meet specific client needs. | Increases customer satisfaction and expands market reach. |

| Improved Durability | Enhances the longevity of fabricated components. | Strengthens brand reputation for reliability and performance. |

Techniques in Precision Fabrication

AP Precision: Leading the Way in Advanced Metal Fabrication continues to set benchmarks in the field through its diverse array of precision fabrication techniques. By effectively utilizing metals and advanced materials, the company ensures that each phase of the manufacturing process is optimized for quality and efficiency. One standout method is fiber-laser metal fabrication, which allows for intricate designs and accurate assembly with minimal waste. The welding department employs proven manufacturing systems to address complex pipe fabrication projects, ensuring that all industrial manufacturing needs are met with precision. As technological advances propel the industry forward, AP Precision remains committed to delivering integrated manufacturing solutions that align with evolving manufacturing needs.

- Emphasis on sustainable practices to reduce waste and enhance efficiency.

- Utilization of CNC machining for high-precision components.

- Implementation of automated workflows to increase production speed.

- Continuous training and development programs for skilled technicians.

- Adoption of advanced software for design and simulation.

- Close collaboration with clients to ensure tailored solutions.

- Regular investment in state-of-the-art technology and equipment.

Overview of Precision Fabrication Techniques

Precision fabrication encompasses a range of advanced techniques that leverage cutting-edge technology to create accurate designs from various alloys. At AP Precision: Leading the Way in Advanced Metal Fabrication, the focus on operational advances ensures that the manufacturing process for products like bicycle fabrication and brass laser components meets the highest standards. With a state-of-the-art factory spanning thousands of square feet, AP Precision utilizes preferred laser technology to work with stainless steel and brass alloys efficiently.

The role of metals pioneers in enhancing fabrication techniques has led to remarkable innovations in the industry. Emphasizing precision, companies like AP Precision: Leading the Way in Advanced Metal Fabrication have adopted processes that maximize accuracy and efficiency. These methods not only improve the quality of the end products but also reduce waste and increase production speed. The integration of various alloys into the fabrication process allows for versatility in manufacturing while maintaining strict tolerances in design.

Advanced Technologies in Precision Fabrication

AP Precision: Leading the Way in Advanced Metal Fabrication is at the forefront of integrating cutting-edge technologies into its operations. The utilization of advanced welding services ensures robust connections in various assemblies. With a focus on brass laser cutting, the company can achieve fine details and intricate designs in its projects. Equipped with state-of-the-art laser-cutting machines, AP Precision delivers precise parts tailored to meet specific design specifications. This commitment to precision enhances the quality of the final products made from various alloys and plate metals.

Emphasizing efficient methods in its production processes, AP Precision employs CAD/CNC design principles to streamline material preparation. This technology allows for the accurate production of components that meet stringent design requirements. The incorporation of US-made contract manufacturing further supports AP Precision’s goal of delivering exceptional quality while maintaining industry-leading standards. These innovative practices position AP Precision: Leading the Way in Advanced Metal Fabrication as a key player in the evolving landscape of metal fabrication, ensuring that their offerings remain competitive and reliable.

AP Precision’s Innovations in Metal Fabrication

With a commitment to excellence, AP Precision: Leading the Way in Advanced Metal Fabrication invests in state-of-the-art machinery and technology solutions that elevate the standards of the industry. The use of specialized machinery allows skilled craftsmen to handle diverse materials, including laser cut brass, to create components with precise angles and accurate technical prints. Each project benefits from advanced techniques that ensure high-quality finish coatings, setting AP Precision apart from conventional laser cutting practices. This innovative approach underscores the company’s dedication to delivering exceptional results through the craftsmanship and precision that define its legacy.

| Innovation | Description | Benefits |

|---|---|---|

| Advanced Laser Cutting | Utilization of state-of-the-art laser technology for intricate cuts. | Enhanced precision and faster turnaround times. |

| Precision Engineering | Employing skilled craftsmen and sophisticated machinery. | High-quality finishing and adherence to technical specifications. |

| Custom Material Handling | Specialized processes catering to diverse materials like brass. | Ability to create unique components tailored to client needs. |

| Finish Coating Techniques | Advanced techniques for a superior product finish. | Increased durability and aesthetic appeal of final products. |

Cutting-Edge Equipment and Technology

AP Precision: Leading the Way in Advanced Metal Fabrication employs state-of-the-art equipment to achieve incredibly accurate cutting across various materials. This advanced technology allows for the creation of intricate designs while ensuring the ability to cost-effectively manufacture components tailored to clients’ specifications. With a focus on high production and efficiency, AP Precision employs techniques that maximize output without compromising quality.

The integration of different laser angles and cutting methods enhances the versatility of machining services offered by AP Precision: Leading the Way in Advanced Metal Fabrication. Talented engineers constantly seek out advances in fabrication technology, ensuring the team stays at the forefront of the industry. This commitment to innovation allows AP Precision to deliver exceptional manufacturing services that meet the diverse needs of their clientele.

Case Studies of Successful Projects

AP Precision: Leading the Way in Advanced Metal Fabrication has successfully delivered numerous projects that highlight its expertise in the competitive electronics industry. One noteworthy case involved the manufacturing of a complex device that required precision electrical assembly. Utilizing state-of-the-art inspection techniques, the team ensured that every component met stringent quality standards. The project leveraged highly-automated machines and advanced solutions to optimize the process, resulting in high-quality production within a square-foot factory designed for efficiency.

Another significant project demonstrated AP Precision’s flexibility and adaptability in using various techniques tailored to client needs. The incorporation of advanced manufacturing software streamlined the hardware insertion process, facilitating seamless integration of components. This commitment to innovation not only reaffirmed AP Precision’s reputation in the industry but also underscored its leadership role in precision fabrication. Each case study serves as a testament to the company’s dedication to excellence in advanced metal fabrication.

Comprehensive Metal Fabrication Guide

AP Precision: Leading the Way in Advanced Metal Fabrication excels in delivering top-notch services through a dedication to precision and quality. The company employs advanced measurement tools and the latest devices, ensuring accurate results in every project. With a team of quality engineers and high-paid technicians, AP Precision maintains high standards across all industrial projects. The presence of senior welders with extensive experience and weld certifications guarantees reliability and safety. Their capabilities also include in-house powder coating, allowing for enhanced finish and durability of heavy materials. This commitment to operational efficiency and excellence is what sets AP Precision apart in the competitive landscape of metal fabrication.

Conclusion

The journey of AP Precision: Leading the Way in Advanced Metal Fabrication showcases its commitment to meeting required specifications through meticulous attention to initial designs and the production of desired components. Utilizing cutting-edge CAD/CNC technologies, the company ensures that each piece produced is precise and adheres to the highest standards. The integration of advanced bending machinery enhances their capabilities, allowing for a variety of different manufacturing services that cater to diverse industry needs. By continually evolving its techniques and technologies, AP Precision not only reinforces its reputation but also sets new benchmarks in the realm of metal fabrication.

FAQS

How does AP Precision ensure high quality metal fabrication projects using various metals and materials?

AP Precision utilizes metals such as aluminium in our ft. factory to produce high quality metal parts for diverse metal fabrication projects.

What methods does AP Precision use to effectively utilize metals and materials in their advanced metal fabrication processes?

AP Precision effectively utilizes metals and materials by implementing state-of-the-art technology and quality control measures, ensuring optimal performance and durability in their fabrication projects. The commitment to excellence in working with various metals and materials allows them to deliver superior results and meet the diverse needs of their clients.

How does AP Precision adapt its techniques to effectively utilize metals and materials in diverse fabrication projects?

AP Precision employs innovative approaches and cutting-edge technology to ensure that they can effectively utilize metals/materials across various fabrication projects, optimizing processes and enhancing the final products.

What innovative technologies does AP Precision employ to enhance its capabilities in advanced metal fabrication?

AP Precision utilizes a range of innovative technologies, including laser cutting, CNC machining, and robotic welding, to enhance its capabilities in advanced metal fabrication, ensuring precision and efficiency in projects across various industries.

What measures does AP Precision take to maintain consistency in their advanced metal fabrication quality?

AP Precision implements strict quality control measures during the fabrication process, utilizing advanced technologies and techniques to ensure consistent results across all metal projects. This dedication to quality is reflected in their commitment to meeting industry standards and client specifications.

Comments are closed.