The Invisible Power: A Comparative Study of Dielectric Constants Among Common Semiconductor Materials

Dielectric constant (ϵ), or relative permittivity, is a measure of a material’s ability to store electrical energy in an electric field. The values of dielectric constants vary significantly among materials, and semiconductors lie somewhere between conductors and insulators. In this article, we will explore how these dielectric constants differ among common semiconductor materials.

Understanding the Dielectric Constant

The dielectric constant is a dimensionless value which represents the extent to which a material can become polarized under an applied electric field. It directly influences the capacitance of a capacitor when the material is used as the dielectric between the conducting plates. The greater the dielectric constant, the higher the capacitance and the more electrical energy the material can store.

Silicon Dioxide: The Established Player

Silicon Dioxide (SiO2) is the most commonly used dielectric material in the microelectronic industry, primarily due to its excellent insulating properties, ease of deposition, and compatibility with silicon-based semiconductors. It has a dielectric constant of about 3.9, setting a reference point for other high-k and low-k dielectric materials.

High-k Dielectrics: The Powerful Contenders

High-k dielectrics, like Hafnium Oxide (HfO2) and Tantalum Pentoxide (Ta2O5), are materials with high dielectric constants (20-25). These materials are used as the gate dielectric in advanced Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs). High-k dielectrics are instrumental in reducing gate leakage current, thereby improving device performance.

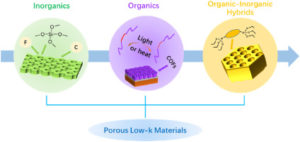

Low-k Dielectrics: The Lightweight Champions

Low-k dielectrics are characterized by their low dielectric constants (lower than that of SiO2). These materials, such as silicon-based polymers and certain porous materials, are used as insulating layers between metal interconnects in integrated circuits to reduce crosstalk and power dissipation.

Polymer Dielectrics: The Flexible Choice

Polymer dielectrics, like Polyethylene (PE) and Polypropylene (PP), offer lower dielectric constants (~2.0) and high dielectric strength. They are used in capacitors due to their high breakdown field strength, good dielectric properties, and mechanical flexibility.

Factors Influencing Dielectric Constants

Several factors, including material composition, structure, and temperature, can affect the dielectric constant. It is also important to consider dielectric loss, which refers to the energy lost in the form of heat during polarization and depolarization cycles. Ideally, a good dielectric material should have a high dielectric constant and low dielectric loss.

Conclusion

The dielectric constant of semiconductor materials is a vital factor in device design and performance. As electronic devices continue to scale down and demand more power, the importance of understanding and manipulating these constants grows. By exploring different materials and tweaking their properties, scientists and engineers pave the way for future advancements in semiconductor technology.

Comments are closed.